‘Like all our Christmases coming at once’ – ‘Formidable’ new laser cutter added to Boston-area factory after £300,000-spend

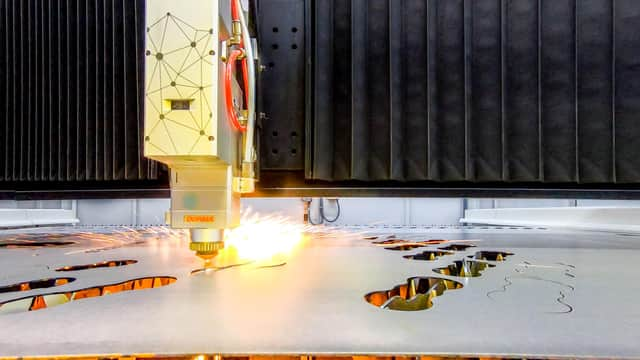

The ‘formidable’ 2kW fibre optic device at Scotts Precision Manufacturing, in Eastville, represents a £300,000-plus investment in the operation there.

The business – an agricultural machinery manufacturer – intends to use the kit to not only make parts for its own range of products, but offer it as a service to others, seeing it join the likes of computer-aided design, machining, sheet metal pressing, welding and painting.

Advertisement

Hide AdAdvertisement

Hide AdIt follows a recently completed £275,000 expansion project at the site.

Managing director Derek Scott said: “This is a massive step forward for a company of our relatively small size and a great investment for our future as we look to grow our product range. The majority of our sales are export and that’s where we see the most growth in the next five to 10 years. It is essential that we can be as efficient as possible to take on the bigger established names in our industry and having access to such a formidable piece of engineering technology is like all our Christmases coming at once”

As well as cutting, the device is able to etch (part numbers or logos, for example). The energy usage is comparable to running two electric kettles, the business says.

Mr Scott added: “I honestly thought we would be several years away from affording this level of equipment, but with technology and manufacturing moving at such a rate these days the cost of high-powered fibre optic laser cutters can now be considered.

Advertisement

Hide AdAdvertisement

Hide Ad“But it’s only with the grant support from the European Agricultural Fund for Rural Development that has got us over the line. All done with the building work and steel stock we have invested well over £300,000 on this project, but at the same time not only given security to our existing team but to create two more highly skilled positions within the company.”